Product Description

Product Description

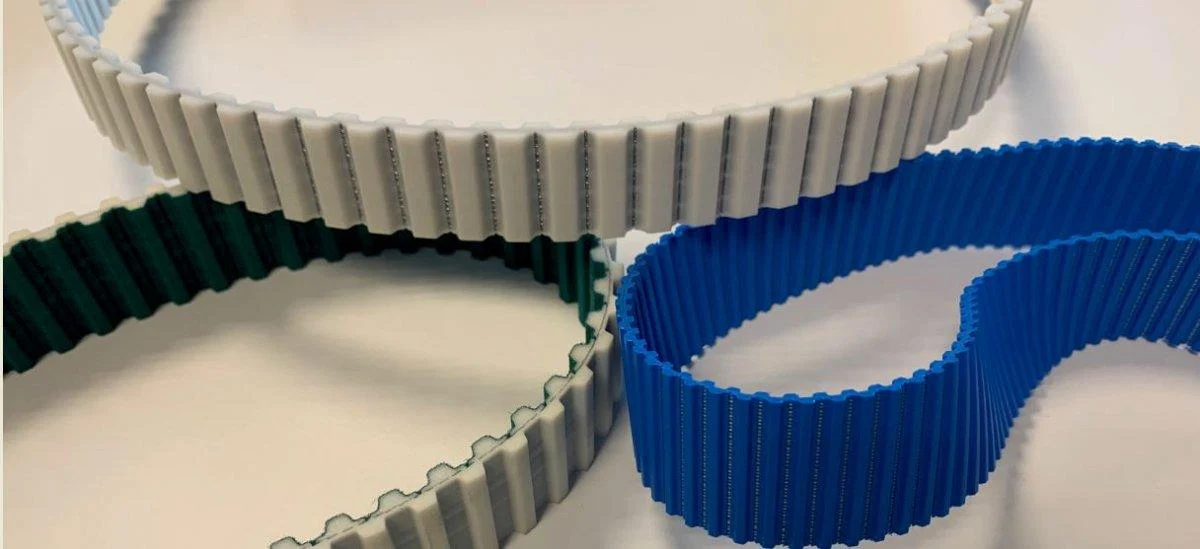

We can provide V-belts, conveyor belts, agricultural machinery belts, industrial belts,timing belts.

Please tell us the parameters, then we can quote in soonest.

Product Parameters

Packaging & Shipping

Our Advantages

1. We have over 10 years’ experience.

2. OEM or Non-Standard Bearings: Any requirement for Non-standard bearings is easily fulfilled by us due to our vast knowledge and links in the industry.

3. After Sales Service and Technical Assistance: Our company provides after-sales service and technical assistance as per the customer’s requirements and needs.

4. Quick Delivery: Our company provides just-in-time delivery with our streamlined supply chain.

5.We attend promptly to any customer questions. We believe that if our customers are satisfied then it proves our worth. Our customers are always given quick support.

Please contact us immediately if you have any questions.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the various mounting options and installations for V-belt tensioners in different settings?

Mounting options and installations for V-belt tensioners can vary depending on the specific application and setting. Different configurations are available to accommodate diverse space constraints, accessibility requirements, and tensioning force adjustments. Here’s a detailed description of the various mounting options and installations for V-belt tensioners:

- Fixed Mounting:

- Adjustable Mounting:

- Spring-Loaded Mounting:

- Separate Tensioner Assembly:

- Multi-Tensioner Systems:

In a fixed mounting configuration, the tensioner is permanently attached to a fixed point, such as a machine frame or structure. This type of installation is commonly used in applications where the belt tension is set at a specific value and does not require frequent adjustment. Fixed mounting provides stability and ensures that the tensioner remains in a fixed position, maintaining consistent tension over time. It is suitable for applications where space is limited and where the tensioning force does not need to be frequently modified.

Adjustable mounting configurations allow for easy tension adjustment of the V-belt. These tensioners feature a mechanism that enables the adjustment of the tensioning force by changing the position of the tensioner relative to the belt and pulleys. Common adjustable tensioners include those with slotted mounting holes or adjustable arms. This type of installation is suitable for applications where the tensioning force needs to be periodically adjusted to maintain optimal belt performance. Adjustable mounting provides flexibility and allows for fine-tuning the tension based on changing operating conditions or belt wear.

Spring-loaded tensioners incorporate a spring mechanism to automatically maintain the desired tension in the V-belt system. These tensioners feature a spring that applies a constant force on the belt, compensating for belt elongation and maintaining proper tension. Spring-loaded tensioners are commonly used in applications where there are fluctuations in load or thermal expansion/contraction of the belt. The spring mechanism ensures continuous tension adjustment, reducing the need for manual intervention and providing consistent tension across varying operating conditions.

In some cases, a separate tensioner assembly is used instead of mounting the tensioner directly to the machine frame or structure. A separate tensioner assembly consists of a bracket or support arm that is attached to the machine or structure, and the tensioner itself is mounted on the bracket or arm. This configuration allows for flexibility in positioning the tensioner and provides ease of installation and maintenance. It is particularly useful in applications where space constraints or accessibility limitations make direct mounting challenging.

In certain applications, multiple tensioners may be used within a V-belt system to ensure proper tension distribution and alignment. Multi-tensioner systems utilize a combination of tensioner types and mounting configurations to achieve optimal belt tensioning across multiple belts and pulleys. This configuration is commonly employed in complex drive systems with multiple belts or long-span belt setups. By using multiple tensioners strategically positioned along the belt path, consistent tension can be maintained, minimizing belt slippage, and maximizing power transmission efficiency.

When selecting the appropriate mounting option and installation for a V-belt tensioner, it’s important to consider factors such as space constraints, tensioning force requirements, accessibility for maintenance, and the specific needs of the application. Manufacturers typically provide guidelines and recommendations for the suitable mounting options and installations for their tensioner products. Following these guidelines, along with considering the specific requirements of the V-belt system, will help ensure the proper integration and effective operation of the tensioner within the application.

Can you provide guidance on selecting and sizing V-belt tensioners for specific V-belt applications?

Yes, selecting and sizing V-belt tensioners for specific V-belt applications requires careful consideration of various factors. Here’s a detailed guidance on how to select and size V-belt tensioners:

- Understand the Application Requirements:

- Determine the Tensioning Force:

- Consider Belt Type and Size:

- Assess Space Constraints and Mounting Options:

- Consider Environmental Factors:

- Consult Manufacturer Specifications and Guidelines:

- Consider Maintenance and Serviceability:

- Consider Cost and Long-Term Value:

Begin by understanding the specific requirements of the V-belt application. Consider factors such as the power transmission requirements, load conditions, operating speed, and environmental conditions. This information will help determine the appropriate tension force and other specifications needed for the tensioner.

Calculate the required tensioning force for the V-belt system. The tensioning force depends on factors such as the power being transmitted, the coefficient of friction between the belt and pulleys, and the belt’s characteristics. Manufacturers typically provide tension force guidelines based on belt type and application. Ensure that the selected tensioner can provide the required tensioning force within the desired operating range.

Take into account the type and size of the V-belt being used. Different belt types, such as classical V-belts, narrow V-belts, or synchronous belts, have specific design and performance characteristics. The tensioner should be compatible with the chosen belt type and size. Consider factors such as belt width, profile dimensions, and load capacity when selecting the tensioner.

Evaluate the available space and mounting options in the application. The tensioner should be sized to fit within the available space and align properly with the pulleys. Consider factors such as the tensioner’s dimensions, mounting configurations (e.g., fixed, adjustable, spring-loaded), and accessibility for installation and maintenance.

Take into account the environmental conditions in which the V-belt system will operate. Factors such as temperature extremes, humidity, dust, and chemical exposure can impact the performance and longevity of the tensioner. Select a tensioner that is designed to withstand the specific environmental conditions of the application.

Refer to the manufacturer’s specifications and guidelines for the tensioner. Manufacturers often provide detailed information on tensioner selection, including tension force ranges, belt compatibility, operating limits, and installation instructions. Consult these resources to ensure the chosen tensioner meets the application requirements and aligns with industry standards.

Evaluate the tensioner’s maintenance and serviceability requirements. Consider factors such as the ease of tension adjustment, access for inspection and maintenance, and the availability of replacement parts. A tensioner that is easy to maintain and service can contribute to the longevity and reliability of the V-belt system.

Finally, consider the cost and long-term value of the tensioner. Evaluate factors such as the initial purchase cost, expected lifespan, and the overall value provided by the tensioner in terms of performance, reliability, and maintenance requirements. While it’s important to consider budget constraints, prioritize selecting a tensioner that meets the application requirements and offers long-term value rather than solely focusing on the upfront cost.

By following these guidelines and considering the specific requirements of the V-belt application, you can select and size V-belt tensioners that are well-suited for the intended use. Remember to consult manufacturers’ specifications and guidelines for detailed information and to ensure proper integration and optimal performance of the tensioner within the V-belt system.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery where optimal belt functionality is essential. The design and characteristics of V-belts make them suitable for applications that require high torque transmission, durability, and reliable power transfer. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are commonly used:

- Automotive Industry:

- Industrial Machinery:

- HVAC Systems:

- Power Generation:

- Agricultural Machinery:

The automotive industry is one of the primary sectors where V-belt tensioners are commonly utilized. V-belts are used in automotive engines to drive various components such as the alternator, water pump, power steering pump, and air conditioning compressor. V-belt tensioners ensure proper tensioning of the belts, allowing for efficient power transmission and reliable operation of these critical automotive systems.

V-belt tensioners find extensive use in a wide range of industrial machinery and equipment. Industries such as manufacturing, mining, agriculture, construction, and material handling rely on V-belt-driven systems for power transmission. V-belts are commonly found in machinery such as conveyor systems, pumps, compressors, fans, blowers, and generators. V-belt tensioners play a crucial role in maintaining optimal tension, preventing belt slippage, and ensuring reliable and efficient operation of these industrial systems.

Heating, ventilation, and air conditioning (HVAC) systems often incorporate V-belt-driven components. V-belt tensioners are used to ensure proper tensioning of the belts in HVAC systems, which may include components like HVAC fans, blowers, and pumps. The tensioners help maintain reliable power transmission, prevent belt slippage, and ensure efficient operation of the HVAC equipment, contributing to effective climate control in various settings such as commercial buildings, residential complexes, and industrial facilities.

In power generation facilities, V-belt tensioners are commonly employed in equipment such as generators and turbines. V-belts are used to transmit power from the prime mover to the generator or turbine, and the tensioners ensure proper belt tension to maintain efficient power transfer. V-belt tensioners play a vital role in power generation applications, helping to optimize performance, prevent belt slippage, and ensure reliable operation of the power generation equipment.

Agricultural machinery and equipment, including tractors, combines, and agricultural implements, often rely on V-belt-driven systems. V-belts are used to transfer power to various agricultural components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners in agricultural machinery help maintain the proper tension in the belts, ensuring efficient power transmission and reliable operation in demanding agricultural environments.

V-belt tensioners are also utilized in other industries and machinery such as marine applications (e.g., marine engines and propulsion systems), construction equipment (e.g., concrete mixers and excavators), and woodworking machinery (e.g., saws and planers). These tensioners are designed to accommodate the specific requirements of each industry and application, ensuring optimal belt functionality, reliable power transmission, and extended belt life.

editor by CX 2024-03-07