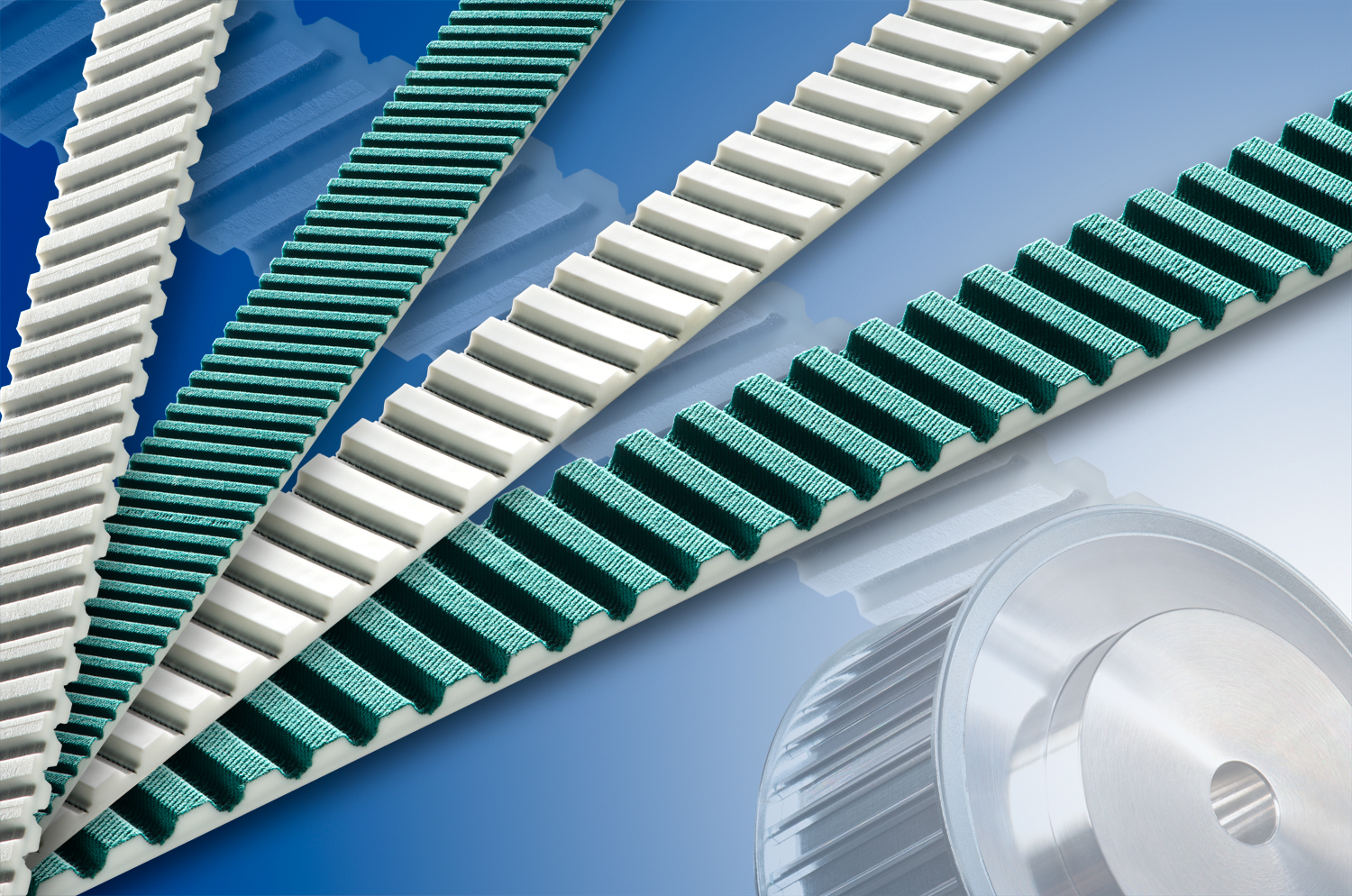

Product Description

NEED TO KNOW BEFORE BUYING

Thank you for browsing our product.

All our product can be customized as per your request or as per your drawings, please feel freel to contact us any time by e-Mail for quicker respond to your inquiry.

LSD Industrial Belt Co., Ltd is a leading manufacturer of high-quality industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. With our expertise and dedication, we have established ourselves as a trusted supplier in the industry.

Operating from 3 well-equipped factories, we specialize in the production of industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. Each factory focuses on delivering exceptional quality products tailored to the specific requirements of our clients.

Our goal is to provide a one-stop shop for our clients in the transmission industry. By offering a comprehensive range of transmission components, we aim to streamline the procurement process and simplify supply chain management for our customers. From industrial belts to timing pulleys/sprockets, we ensure that our product portfolio covers all the essential transmission elements.

As a preferred supplier for renowned Asian manufacturers such as Media and Lesso, we take pride in our strong business partnerships. Located in HangZhou City, ZheJiang Province, we benefit from being in a business incubator known for fostering high-tech industrial chains.

Our commitment to CZPT extends beyond manufacturing. We have successfully exported our products to various regions, including the USA, Canada, Europe, UAE, Africa, and Asia. Our clients have consistently expressed high satisfaction with our products and after-sales service.

To ensure efficient service, we maintain a comprehensive inventory of commonly used items. This allows us to promptly fulfill small quantity orders without any complications.

At CZPT Industrial Belt Co., Ltd, we combine superior manufacturing capabilities, reliable supply chain management, and a customer-centric approach to deliver exceptional products and services to our valued clients worldwide. Our goal of being a one-stop shop in the transmission industry sets us apart, as we strive to provide a seamless experience for our customers, from initial inquiry to final delivery.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Toothed Belt |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you describe the various mounting options and installations for V-belt tensioners in different settings?

Mounting options and installations for V-belt tensioners can vary depending on the specific application and setting. Different configurations are available to accommodate diverse space constraints, accessibility requirements, and tensioning force adjustments. Here’s a detailed description of the various mounting options and installations for V-belt tensioners:

- Fixed Mounting:

- Adjustable Mounting:

- Spring-Loaded Mounting:

- Separate Tensioner Assembly:

- Multi-Tensioner Systems:

In a fixed mounting configuration, the tensioner is permanently attached to a fixed point, such as a machine frame or structure. This type of installation is commonly used in applications where the belt tension is set at a specific value and does not require frequent adjustment. Fixed mounting provides stability and ensures that the tensioner remains in a fixed position, maintaining consistent tension over time. It is suitable for applications where space is limited and where the tensioning force does not need to be frequently modified.

Adjustable mounting configurations allow for easy tension adjustment of the V-belt. These tensioners feature a mechanism that enables the adjustment of the tensioning force by changing the position of the tensioner relative to the belt and pulleys. Common adjustable tensioners include those with slotted mounting holes or adjustable arms. This type of installation is suitable for applications where the tensioning force needs to be periodically adjusted to maintain optimal belt performance. Adjustable mounting provides flexibility and allows for fine-tuning the tension based on changing operating conditions or belt wear.

Spring-loaded tensioners incorporate a spring mechanism to automatically maintain the desired tension in the V-belt system. These tensioners feature a spring that applies a constant force on the belt, compensating for belt elongation and maintaining proper tension. Spring-loaded tensioners are commonly used in applications where there are fluctuations in load or thermal expansion/contraction of the belt. The spring mechanism ensures continuous tension adjustment, reducing the need for manual intervention and providing consistent tension across varying operating conditions.

In some cases, a separate tensioner assembly is used instead of mounting the tensioner directly to the machine frame or structure. A separate tensioner assembly consists of a bracket or support arm that is attached to the machine or structure, and the tensioner itself is mounted on the bracket or arm. This configuration allows for flexibility in positioning the tensioner and provides ease of installation and maintenance. It is particularly useful in applications where space constraints or accessibility limitations make direct mounting challenging.

In certain applications, multiple tensioners may be used within a V-belt system to ensure proper tension distribution and alignment. Multi-tensioner systems utilize a combination of tensioner types and mounting configurations to achieve optimal belt tensioning across multiple belts and pulleys. This configuration is commonly employed in complex drive systems with multiple belts or long-span belt setups. By using multiple tensioners strategically positioned along the belt path, consistent tension can be maintained, minimizing belt slippage, and maximizing power transmission efficiency.

When selecting the appropriate mounting option and installation for a V-belt tensioner, it’s important to consider factors such as space constraints, tensioning force requirements, accessibility for maintenance, and the specific needs of the application. Manufacturers typically provide guidelines and recommendations for the suitable mounting options and installations for their tensioner products. Following these guidelines, along with considering the specific requirements of the V-belt system, will help ensure the proper integration and effective operation of the tensioner within the application.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

Can you provide examples of products or machinery that rely on V-belt tensioners for efficient operation?

V-belt tensioners play a critical role in ensuring efficient operation in various products and machinery across different industries. Here are some examples of products and machinery that rely on V-belt tensioners:

- Automotive Engines:

- Industrial Machinery:

- HVAC Systems:

- Power Generation Equipment:

- Agricultural Machinery:

- Woodworking Machinery:

In automotive engines, V-belt tensioners are essential for the proper functioning of various components. Examples include the alternator, water pump, power steering pump, air conditioning compressor, and superchargers. V-belt tensioners ensure optimal tension in the belts, preventing slippage and ensuring efficient power transfer to these components.

A wide range of industrial machinery relies on V-belt tensioners for efficient operation. This includes conveyor systems, pumps, compressors, fans, blowers, and generators used in manufacturing plants, mining operations, construction sites, and material handling facilities. V-belt tensioners help maintain proper tension, preventing belt slippage and ensuring reliable power transmission.

Heating, ventilation, and air conditioning (HVAC) systems commonly incorporate V-belt tensioners. These tensioners are used in HVAC fans, blowers, and pumps, which are critical components of climate control systems in buildings and industrial facilities. Proper tensioning of V-belts with tensioners ensures efficient operation and optimal performance of the HVAC equipment.

V-belt tensioners are vital in power generation equipment such as generators and turbines. These tensioners help maintain the proper tension in the belts, ensuring efficient power transfer from the prime mover to the generator or turbine. Reliable tensioning is crucial for the optimal performance and operation of power generation systems.

Agricultural machinery heavily relies on V-belt tensioners. Tractors, combines, and various agricultural implements use V-belts to transfer power to components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners ensure proper tensioning, preventing slippage and ensuring efficient operation in demanding agricultural environments.

Woodworking machinery, such as saws, planers, and sanders, often utilize V-belt tensioners. These tensioners help maintain the proper tension in the V-belts that drive the cutting tools and other components of the woodworking equipment. Efficient tensioning ensures precise and reliable operation in woodworking applications.

These are just a few examples of the wide range of products and machinery that rely on V-belt tensioners for efficient operation. V-belt tensioners are utilized in various other industries and applications, including marine propulsion systems, construction equipment, mining machinery, and more. The specific use of V-belt tensioners depends on the requirements of the application, ensuring reliable power transmission, extended belt life, and optimal performance.

editor by CX 2024-01-09