Product Description

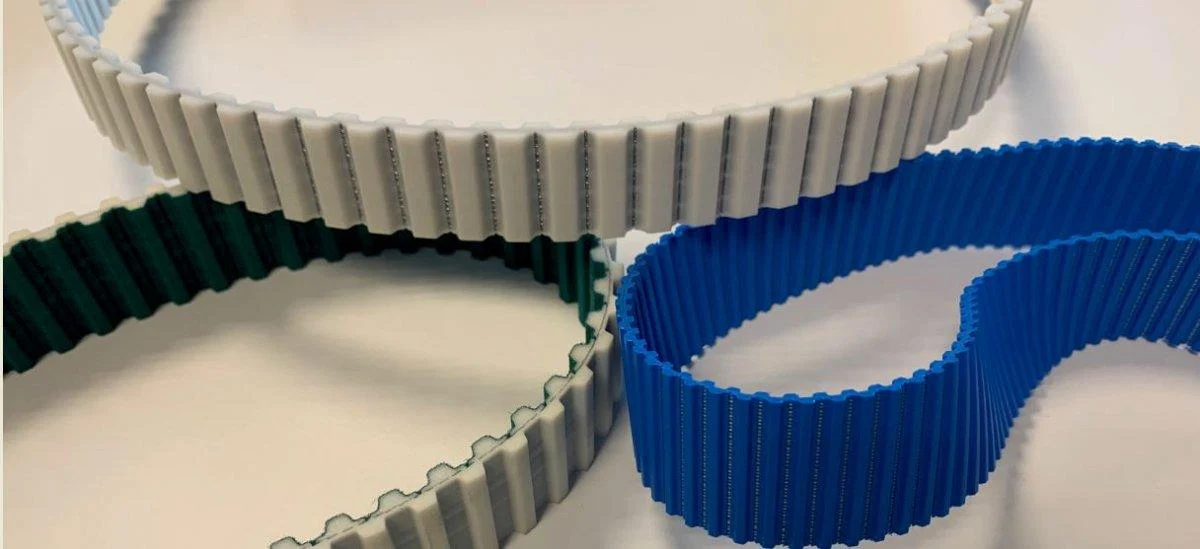

Products Description of HNBR, Cr Material 124ru26-T CZPT Tfl Timing Belt Replacement Za, Zb, Ru, Yu, My, Mr, Zbs, S8m, Sp, Htdn

Basic Technical Parameter:

No. of Teeth: 124.

Belt width:26mm

Teflon coating

Rubber material: HNBR, CR.

Belt: HNBR, High-quality neoprene (CR)as the main raw materials( imported from Japan)

Skeleton materials: Glass Fiber(imported from Japan)

Tooth surface: Nylon 66 high

OFT timing belt Technical Parameter:

| Type | Pb(mm) | Ht(mm) | Hs(mm) |

| ZA | 9.525 | 1.91 | 4.10 |

| ZB | 9.525 | 2.29 | 4.50 |

| ZH | 9.525 | 3.50 | 5.50 |

| YH | 8.000 | 3.04 | 5.20 |

| ZR | 9.525 | 3.20 | 5.40 |

| YS | 8.000 | 2.95 | 5.20 |

| ZS | 9.525 | 3.53 | 5.70 |

| ZAS | 9.525 | 2.32 | 4.62 |

| ZBS | 9.525 | 2.80 | 2.80 |

| FS8M | 8.000 | 3.05 | 3.05 |

| YU | 8.000 | 3.11 | 3.11 |

| MY | 8.000 | 3.11 | 3.11 |

| MR | 9.525 | 3.54 | 3.54 |

| RU | 9.525 | 3.56 | 3.56 |

| ZLB | 9.525 | 2.70 | 2.70 |

| ZD | 9.525 | 3.50 | 3.50 |

OEM support

OFT company supplies OEM support, with experience of timing belt design for Italian sports car.

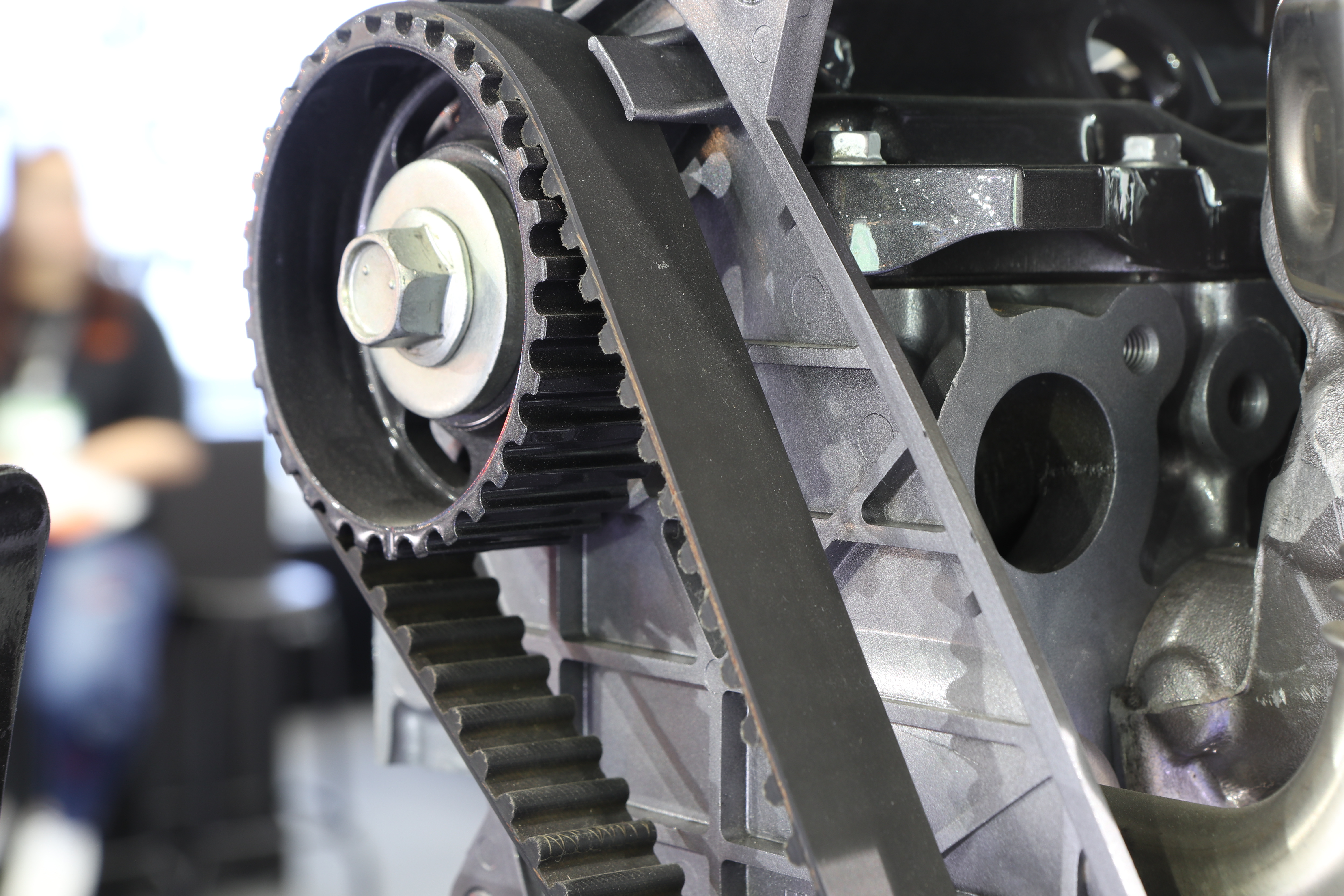

Applications of CZPT timing belt

The timing belt is widely used in office machines, computers, projects, tape-records, domestic appliances, machine tools, medical equipment, etc.

Our Products:

Company Introduction

ZheJiang CZPT TRANSMISSION BELTS CO.LTD., which is further expanded from the existing HangZhou Ophte

Rubber Co., Ltd., is equipped with more sophisticated technology and accurate devices. The factory has been put into operation since Aug. 2012, which covers an area of 33,000 square meters. CZPT is a modernized

enterprise, integrating D&R, production, and marketing.

Since its foundation in 2004, our company has taken technology as the core, committed itself to the development and application of new materials and advanced technology, and achieved significant results. The

quality of its product has been at the leading level of the same industry in China.

Workshop of OFT

We have independently developed the HNBR coating timing belt, one-step vulcanized thickening coated PK belts

with many choices in colors and CR wrapped belts with strengthened intensity.

Shipping details

OFT Transmission Belts mainly serve Aftermarkets, and more than 90% of products are exported to Eastern

Europe, Western Europe, North America, Central, and South America, Oceania, etc.

Free samples supplied by OFT,contact us:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Electric Cars, Motorcycle, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Toothed Belt |

| Samples: |

US$ 150/Roll

1 Roll(Min.Order) | |

|---|

How do V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications?

V-belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of V-belts in various applications. By maintaining proper belt tension, mitigating belt slippage, reducing wear, and minimizing the risk of belt failure, tensioners contribute to improved efficiency and extended belt life. Here’s a detailed explanation of how V-belt tensioners enhance the overall efficiency and lifespan of V-belts:

- Optimal Belt Tension:

- Reduced Belt Slippage:

- Wear Reduction:

- Vibration and Noise Damping:

- Prevention of Belt Failure:

V-belts operate most efficiently when they are running at the correct tension. Over-tensioned or under-tensioned belts can lead to problems such as excessive heat generation, increased wear, and reduced power transmission. V-belt tensioners ensure that the belts are properly tensioned by applying the right amount of force to maintain the desired tension level. This optimizes the power transfer efficiency and minimizes energy losses, resulting in improved overall system efficiency.

Proper tensioning provided by V-belt tensioners helps to minimize belt slippage, which is a common issue in V-belt drive systems. Belt slippage occurs when the belt slips on the pulleys, leading to a loss of power transmission efficiency. Tensioners maintain the necessary tension in the belt, ensuring a positive grip between the belt and the pulleys. By reducing slippage, tensioners help maximize power transfer, improve system efficiency, and prevent premature belt wear due to excessive slipping.

V-belt tensioners help reduce wear on the belts by ensuring proper alignment and tension. Misaligned or poorly tensioned belts can experience increased wear, resulting in premature belt failure. Tensioners keep the belts aligned and tensioned correctly, minimizing lateral movement and excessive belt wear. By reducing wear, tensioners contribute to the extended lifespan of the belts and reduce the need for frequent belt replacements, resulting in cost savings for the application.

V-belt tensioners can also help dampen vibrations and reduce noise in V-belt drive systems. Vibration and noise can occur due to belt oscillation or irregular belt-pulley contact. Tensioners stabilize the belt tension, reducing belt vibrations and associated noise. This not only improves the overall system performance but also enhances the working environment by reducing noise levels.

By maintaining optimal tension and reducing wear, V-belt tensioners help prevent belt failure. Belt failure can result in unexpected downtime, increased maintenance costs, and productivity losses. Tensioners ensure that the belts are properly tensioned and aligned, reducing the risk of belt fatigue, cracking, or premature breakage. This enhances the overall reliability and longevity of the belts, allowing for uninterrupted operation and improved application performance.

In summary, V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications by maintaining optimal tension, reducing belt slippage, minimizing wear, damping vibrations and noise, and preventing belt failure. These benefits result in improved power transmission efficiency, extended belt life, reduced maintenance requirements, and enhanced system reliability. By incorporating well-designed and properly adjusted tensioners, applications can optimize the performance and longevity of V-belts, leading to increased productivity and cost savings.

How do innovations and advancements in V-belt tensioner technology impact their use?

Innovations and advancements in V-belt tensioner technology have a significant impact on their use, leading to improved performance, increased reliability, and enhanced efficiency in various applications. Here’s a detailed explanation of how innovations and advancements in V-belt tensioner technology impact their use:

- Enhanced Tensioning Mechanisms:

- Increased Durability and Reliability:

- Reduced Friction and Energy Losses:

- Integration of Diagnostic and Monitoring Features:

- Application-Specific Customization:

New technologies and design innovations have led to the development of enhanced tensioning mechanisms in V-belt tensioners. These mechanisms offer improved accuracy and consistency in applying the desired tension force to the belts. Advanced tensioner designs may incorporate features such as self-adjusting mechanisms, automatic tension control, or adaptive tensioning systems. These advancements simplify the tensioning process, reduce manual adjustments, and ensure optimal tension levels, leading to improved system performance and reduced maintenance requirements.

Advancements in materials, manufacturing processes, and engineering techniques have resulted in V-belt tensioners with increased durability and reliability. New materials with improved strength and wear resistance, such as advanced polymers or specialized alloys, are being utilized in tensioner construction. Additionally, innovative manufacturing methods allow for tighter tolerances, precise assembly, and better overall quality control. These advancements result in tensioners that can withstand higher loads, resist wear and fatigue, and operate reliably even in demanding environments, enhancing the longevity and reliability of V-belt systems.

New technologies and advancements in V-belt tensioner design have focused on reducing friction and energy losses during power transmission. Friction-reducing coatings, specialized bearing systems, and optimized contact surfaces are employed to minimize energy losses due to belt-pulley interaction. These advancements result in improved power transmission efficiency, reduced heat generation, and lower energy consumption. By reducing friction and energy losses, innovative tensioner technologies contribute to energy savings, lower operating costs, and improved overall system efficiency.

Advancements in V-belt tensioner technology include the integration of diagnostic and monitoring features. Tensioners may incorporate sensors or indicators that provide real-time data on tension levels, belt wear, or system performance. This allows users to monitor the condition of the tensioner and the entire power transmission system, enabling proactive maintenance and preventing unexpected failures. Diagnostic and monitoring capabilities enhance system reliability, optimize maintenance schedules, and reduce downtime, leading to improved operational efficiency.

Advancements in V-belt tensioner technology have facilitated application-specific customization. Manufacturers can now design tensioners to meet the unique requirements of different industries and applications. Customizable features include tensioning force, size, mounting options, and specialized coatings. This flexibility allows for better integration into specific systems, addressing space constraints, load demands, and environmental conditions. Application-specific customization improves overall system performance, reliability, and compatibility.

In summary, innovations and advancements in V-belt tensioner technology have a profound impact on their use. Enhanced tensioning mechanisms, increased durability and reliability, reduced friction and energy losses, integration of diagnostic and monitoring features, and application-specific customization all contribute to improved performance, reliability, efficiency, and compatibility. These advancements enable more efficient power transmission, longer service life, reduced maintenance requirements, and enhanced overall performance of V-belt systems in various industrial and automotive applications.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2023-12-25