Product Description

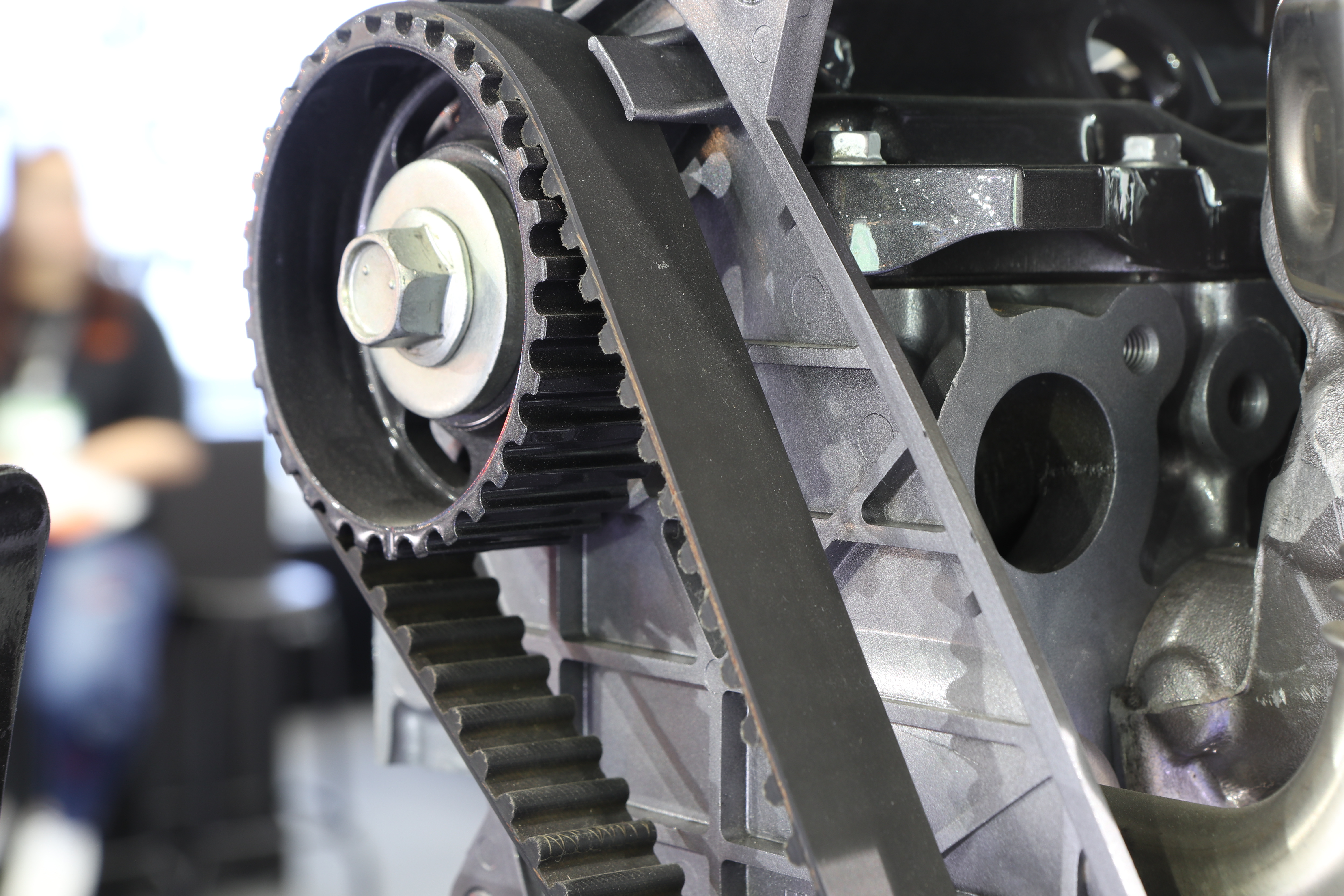

Good Quality Timing Belt Drive Belt Transmission Belt synchronous belt 120zbs19 for Hyundai/Mitsubishi Car/MD197136

| 94175 |

| HYUNDAI | 2413232571 |

| HYUNDAI | MD57190 |

| HYUNDAI | MD098491 |

| HYUNDAI | 2431232830 |

| HYUNDAI | MD157149 |

| HYUNDAI | 2431232820 |

| HYUNDAI | 2431232840 |

| HYUNDAI | 2431232571 |

| HYUNDAI | MD113790 |

| MITSUBISHI | MD197136 |

| MITSUBISHI | MD015701 |

| MITSUBISHI | MD098491 |

| MITSUBISHI | MD145718 |

| MITSUBISHI | MD57190 |

| MITSUBISHI | MD57130 |

| MITSUBISHI | MD157149 |

| MITSUBISHI | MD113790 |

| MITSUBISHI | XD145718 |

Loading.

Description:

L Low-noise operation

L High-efficiency drive

L Accurate transmission

L Anti-cold, Anti-heat, Anti-oil performance

L Abrasion resistance, good tensile strength

L Maintenance-free, high life expectancy

Specifications

Manufacturer PK,Timing,V Belt AND Rubber Brake chamber/ Diaphragm With EPDM CR HNBR Material Genuine Original

Quality Warranty 6,0000-8,0000 KM

Why Choose Us?

1.Our Material Of Rubber Is imported .

2.Our Material Of Glass Fiber Cords Are imported from Japan.Warranty 8,0000-10,0000 KM

3.Other Accessories And Subsidiary Materials Are From The good Brand Suppliers.

4.We Are Professional Perfomance Manufacturer PK,Timing,V Belt AND Rubber Brake Diaphragm

5.Transmission Belts Parts OEM Quality PK Belt Manufacturer GENUINE Quality

| Type | Timing Belt/Cogged V Belt/Wrapped V Belt/ PK Belt/Conveyor Belt/Speed Belt/Fan Belt/ Flat Belt/Ribbed Belt/Round Belt/Banded Belt/ Industrial Synchronous Belt/RUBBER BRAKE DIAPHRAGM |

Material | 1.Rubber is imported from USA and Germany. 2.Glass fiber cords are imported from Japan and Germany. Other accessories and subsidiary materials are from the good brand suppliers now. |

| Information 1 | Belt warranty 6,0000-8,0000 KM | Brand | AIWO,CUSTOMER’S BRAND |

| Information 2 | Manufacturer PK Belt | Certification | TS16949/ISO9001 So On |

| Information 3 | GENUINE Quality | Warranty | 100% CR life span 60,000 to 80,000 kilometers |

| Packaging Size |

Can Be Customized | Delisvery Time |

20-45 Days(depends on order quantity) |

FAQ

1) How can I place order?

A:You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A:After you confirm our PI, we will request you to pay.T/T (bank) and Paypal, Western Union are the most usual ways we are using.

3) What’s the order procedure?

A:First we discuss order details, production details by email or TM.Then we issue you an PI for your confirmation.You will be requested to do pre-paid full payment or deposit before we go into production.After we get the deposit, we start to process the order.We usually need 7-15days if we don’t have the items in stock.Before production has been finished, we will contact you for shipment details, and the balance payment.After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A:Replacement.If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A:We have spot inspection and finished product inspection.We check the goods when they go into next step production procedure. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Timing Belt |

|---|---|

| Feature: | Wear-resistant, Heat-resistant, Tear-resistant, Flame-resistant, Cold-resistant |

| Performance: | Strong Rubber Conveyor Belt |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do materials and coatings play in the performance and longevity of V-belt tensioners?

Materials and coatings play a significant role in the performance and longevity of V-belt tensioners. The choice of materials and the application of appropriate coatings can greatly impact the durability, reliability, and overall effectiveness of the tensioners. Here’s a detailed explanation of the role materials and coatings play in the performance and longevity of V-belt tensioners:

- Material Selection:

- Coatings:

- Zinc or Chrome Plating: These coatings provide excellent corrosion resistance, protecting the tensioner from environmental factors, such as moisture and chemicals. They also enhance the aesthetic appearance of the tensioner.

- Powder Coating: Powder coating is a durable and long-lasting coating option that provides corrosion resistance and improved wear resistance. It can also offer a variety of color options to match specific design requirements.

- Teflon or PTFE Coating: Teflon or PTFE (Polytetrafluoroethylene) coatings offer low friction properties, reducing wear and extending the life of the tensioner. These coatings are particularly useful in applications where minimizing friction and energy losses are critical.

- Ceramic Coating: Ceramic coatings provide excellent hardness and wear resistance. They are often used in high-performance applications where the tensioner is subjected to severe wear and abrasive conditions.

- Benefits for Performance and Longevity:

- Increased Wear Resistance: High-quality materials and coatings can significantly improve the wear resistance of tensioners, reducing the rate of wear and extending their service life. This is particularly important in applications with high belt speeds, heavy loads, or abrasive environments.

- Enhanced Corrosion Protection: Coatings, such as zinc or chrome plating, provide effective corrosion protection, preventing rust and degradation of the tensioner in humid or corrosive environments.

- Reduced Friction: Coatings, such as Teflon or PTFE, reduce friction between the tensioner and the belt, minimizing heat generation and energy losses. This improves the efficiency of the V-belt system and reduces wear on both the tensioner and the belt.

- Improved Surface Hardness: Coatings, such as ceramic coatings, enhance the surface hardness of tensioners, making them more resistant to wear and abrasion. This results in longer-lasting tensioners that can withstand demanding operating conditions.

The selection of materials for V-belt tensioners is crucial as they need to withstand the demanding operating conditions encountered in V-belt systems. High-quality materials with excellent mechanical properties, such as strength, hardness, and wear resistance, are typically chosen. Common materials used for tensioners include metals, such as steel or cast iron, and advanced polymers, such as thermoplastics or thermosetting plastics.

Metal tensioners offer high strength and rigidity, making them suitable for heavy-duty applications with high tension loads. They are also resistant to temperature variations and provide stability under demanding conditions. Polymer tensioners, on the other hand, offer advantages such as lightweight, corrosion resistance, and reduced noise and vibration transmission. The choice between metal and polymer materials depends on the specific requirements of the V-belt system and the operating environment.

Coatings are often applied to the surfaces of V-belt tensioners to enhance their performance and extend their longevity. Coatings provide several benefits, such as improved wear resistance, corrosion protection, reduced friction, and enhanced surface hardness. Here are some commonly used coatings for V-belt tensioners:

The choice of materials and coatings in V-belt tensioners directly impacts their performance and longevity. Here are the key benefits they provide:

In summary, materials and coatings play a vital role in the performance and longevity of V-belt tensioners. The selection of high-quality materials and appropriate coatings ensures that tensioners can withstand the rigors of V-belt systems, resist wear and corrosion, reduce friction, and maintain their effectiveness over an extended service life. Considering the specific requirements of the application and the operating environment, manufacturers choose materials and coatings that optimize the performance and longevity of V-belt tensioners, ultimately contributing to the reliable operation of the V-belt system.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2024-01-03